The Key to Smarter Aggregate Processing through Dry and Wet Classification

Blogs

A road construction project in a remote area that requires high-quality aggregates but has limited water resources, makes wet processing impractical. Here, Dry Classification is the solution, sorting materials without water. Conversely, in a mining facility near a river, where dust control and impurity removal are priorities, Wet Classification ensures cleaner output. These two methods are vital in classification since each is suited to specific environmental and operational needs.

In aggregate processing, achieving the right particle size is key to efficiency and product quality. Classification separates materials based on size, density, and composition. The two primary methods—Dry and Wet Classification—are chosen based on production requirements, material properties, and environmental factors.

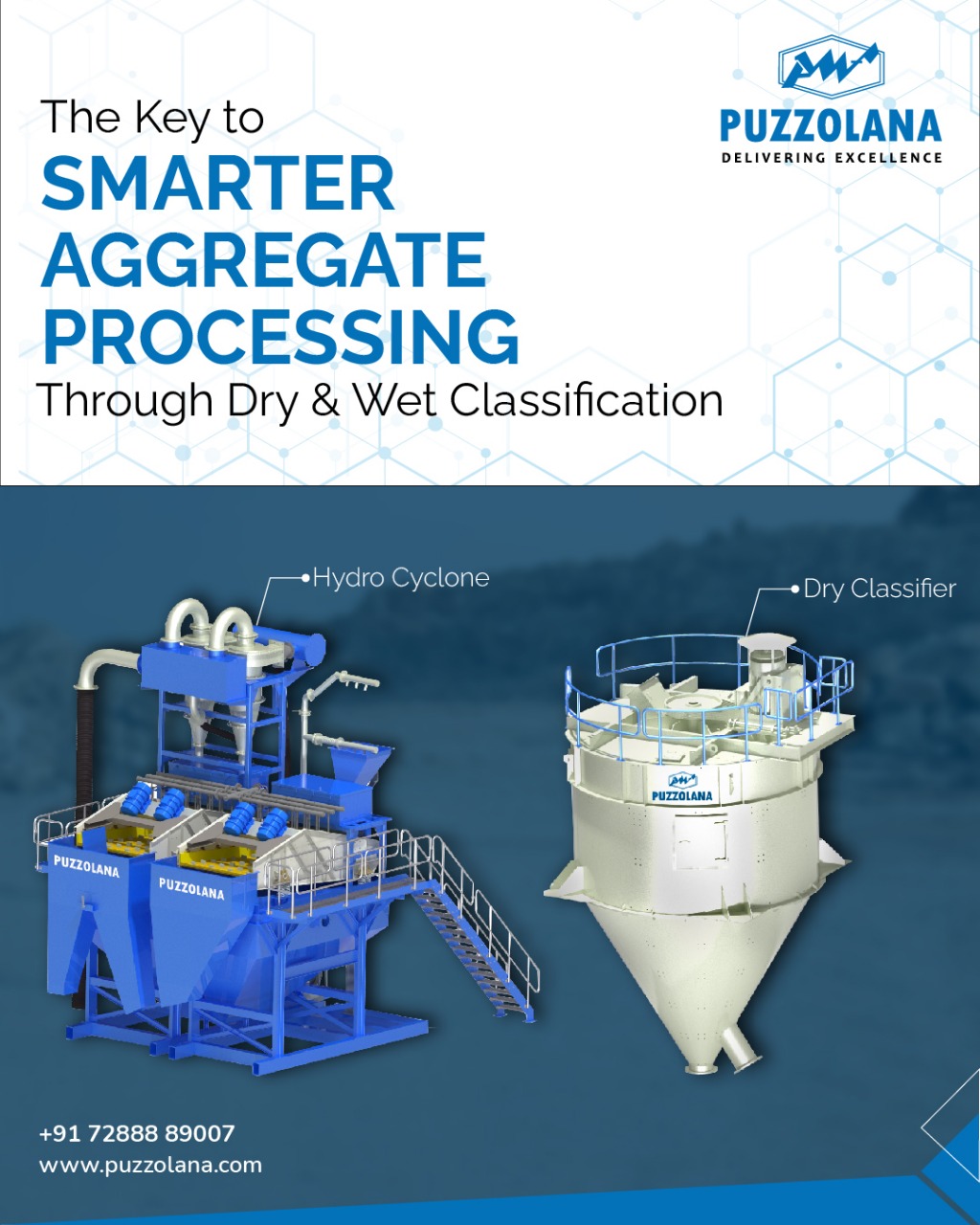

Dry Classification: Efficient Air-Based Separation

Dry Classification is an advanced air-based technique that sorts crushed materials without water. It is ideal for regions with limited water resources or when moisture can affect product quality.

The process begins when crushed material enters an air classifier. High-velocity air lifts finer particles while heavier ones settle for further crushing or screening. This method is cost-effective and eco-friendly, eliminating water use and reducing sludge production. Quarrying and mining industries favor Dry Classification for its sustainability and efficiency.

However, it presents certain challenges. Dust generation requires suppression systems for workplace safety and regulatory compliance. It is also less effective for sticky or moisture-laden materials, which can clump together, reducing classification accuracy.

Wet Classification: Water-Driven Precision and Quality Control

Wet Classification is a highly effective process that utilizes water to separate materials, making it an excellent choice for crushing and screening operations that prioritize dust control, impurity removal, and material refinement.

In this process, crushed material is mixed with water and fed into a classifier, where the water helps to separate particles based on size and density. The water flow facilitates the removal of fine impurities, clay, and silt while ensuring that only the desired, high-quality aggregates remain. This not only improves the final product but also enhances downstream processing efficiency. This method is widely used in sand processing, mining, and construction industries requiring precise material refinement.

While Wet Classification offers superior cleanliness, improved aggregate quality, and reduced dust emissions, it also comes with certain challenges. One significant consideration is its high water consumption, which necessitates efficient management, treatment, and disposal systems to meet environmental regulations. Additionally, the handling of water-based slurry, sedimentation control, and wastewater treatment can add to overall operational costs, making it essential for industries to implement sustainable water recycling solutions.

Choosing the Right Classification Method

Both Dry and Wet Classification play critical roles in aggregate and mineral processing. The choice depends on material type, environmental regulations, production goals, and site conditions. Dry Classification is best for arid regions or industries minimizing water use, while Wet Classification is necessary for applications requiring high-purity, dust-free aggregates.

Selecting the right method boosts efficiency, cuts costs, and optimizes resource management. Choosing the most suitable classification process ensures superior product quality and operational success. Whether processing aggregates for construction, mining, or industrial use, understanding Dry and Wet Classification is essential. Assess your specific needs to enhance productivity and sustainability in your crushing and screening operations. With industry expertise, Puzzolana delivers tailored solutions for both Dry and Wet Classification, seamlessly combining efficiency and reliability across applications.

Looking for the best classification solution for your operations? Connect with Puzzolana today to find the perfect fit for your needs.

View our expansive machinery

With Puzzolana, you have the chance to work with the brightest professionals in the field and be a part of our expanding global footprint. We are looking for motivated professionals to join our team.