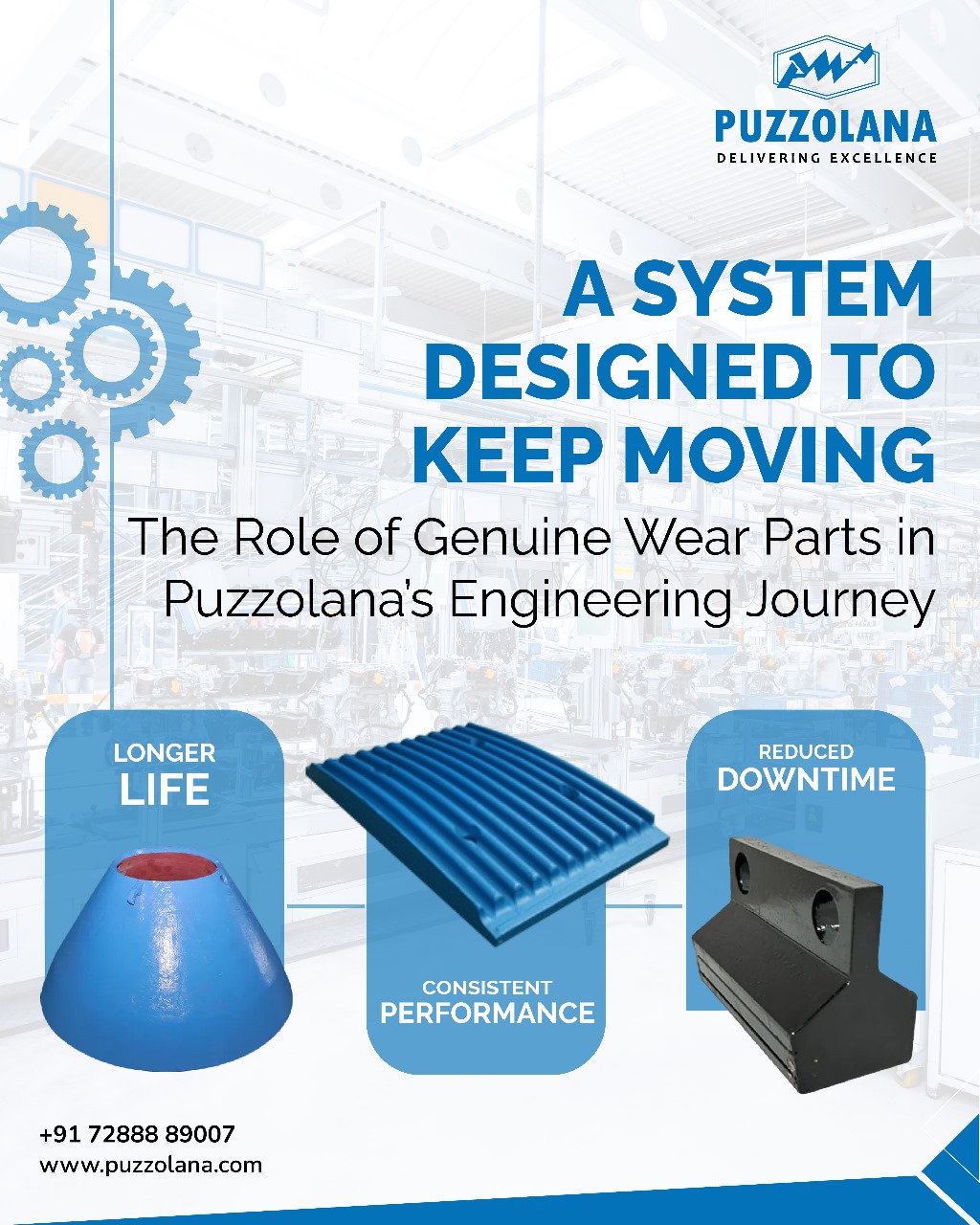

The Role of Genuine Wear Parts in Puzzolana’s Engineering Journey

Blogs

It didn’t begin with a breakdown. It began with a breakthrough.

Over years of operation, one insight emerged from across crushing sites and customer conversations — performance isn’t just a matter of machine size or crushing force. It’s about system harmony. A harmony where every part inside the machine, from liners to tips, works

in rhythm with the original design intent.

This was the moment genuine wear parts moved from supporting roles to central elements in the Puzzolana ecosystem — not as replacements, but as essential contributors to consistency, longevity, and output precision.

Built from the Ground Up: Design Philosophy Meets Field Reality

Puzzolana machines are built for purpose. But maintaining that purpose requires every component to do more than fit — it must function with intent.

This led to a deep design philosophy: no wear part is developed in isolation. Engineering teams review material flow data, analyze chamber load behavior, and examine impact zones. These insights shape the way jaw plates channel force, how liners preserve chamber

geometry, and how blow bars distribute energy without sacrificing structural integrity.

What results is a portfolio of genuine wear parts that support not just durability, but balance. And in high-output plants, balance is performance.

The evolution of genuine wear parts at Puzzolana was never theoretical. It was forged through feedback from the field — from operators, service teams, and inspection logs.

When part longevity improved under certain alloys, it informed material strategy. When liner wear followed predictable curves, chamber design was further refined. When certain feed types demanded specific tip geometry, adjustments were engineered for better flow.

These aren’t modifications. They are reflections of a product line shaped by real-world rhythms — part by part, site by site.

Performance You Don’t Have to Think About

When a machine runs seamlessly, it often goes unnoticed — and that’s the true mark of well-designed wear parts. Genuine components perform without drawing attention. They support the system, reduce fatigue, and extend cycles — all without disrupting the natural

flow of operations.

Each genuine Puzzolana wear part is engineered for alignment with forces, dimensions, and performance expectations. This means every strike, crush, or pass-through is as efficient on day 200 as it was on day one.

It’s not just about reducing downtime. It’s about maintaining continuity.

Puzzolana’s commitment to genuine parts is rooted in long-term thinking. It’s seen in the way plants report reduced power draw, fewer unplanned stoppages, and higher product consistency after switching to system-synced components.

When genuine wear parts are used, machines don’t just run — they stay true to the performance curve they were built for.

That kind of consistency becomes a competitive advantage. Not through force, but through flow.

Preserving Intent, Driving the Future

As the crushing industry evolves toward precision output and smarter operations, wear parts must evolve with it — not just in material strength, but in system sensitivity.

Puzzolana continues to refine its genuine parts offering through better metallurgy, more responsive design, and deeper integration with machine dynamics. The goal isn’t to chase trends — it’s to preserve performance. To ensure that every chamber, every rotor, every

liner operates with intention.

Because performance doesn’t end when a machine is commissioned. It begins again with every shift, every load, and every wear part that’s built to last.

Conclusion: When Every Part Works, the Whole Machine Wins

At Puzzolana, every genuine wear part is more than a component — it’s a continuation of the machine’s original purpose. It carries with it the precision of design, the wisdom of the field, and the commitment to performance that defines everything we build.

When each liner, tip, or plate is engineered to work in sync with the system, performance becomes predictable. Maintenance becomes proactive. And uptime becomes the rule, not the exception.

Genuine wear parts aren’t just built to last — they’re built to keep everything else moving forward.

Because when every part remembers the intent it was made for, every shift tells the same story: consistency, reliability, and crushing confidence — the Puzzolana way.

View our expansive machinery

With Puzzolana, you have the chance to work with the brightest professionals in the field and be a part of our expanding global footprint. We are looking for motivated professionals to join our team.