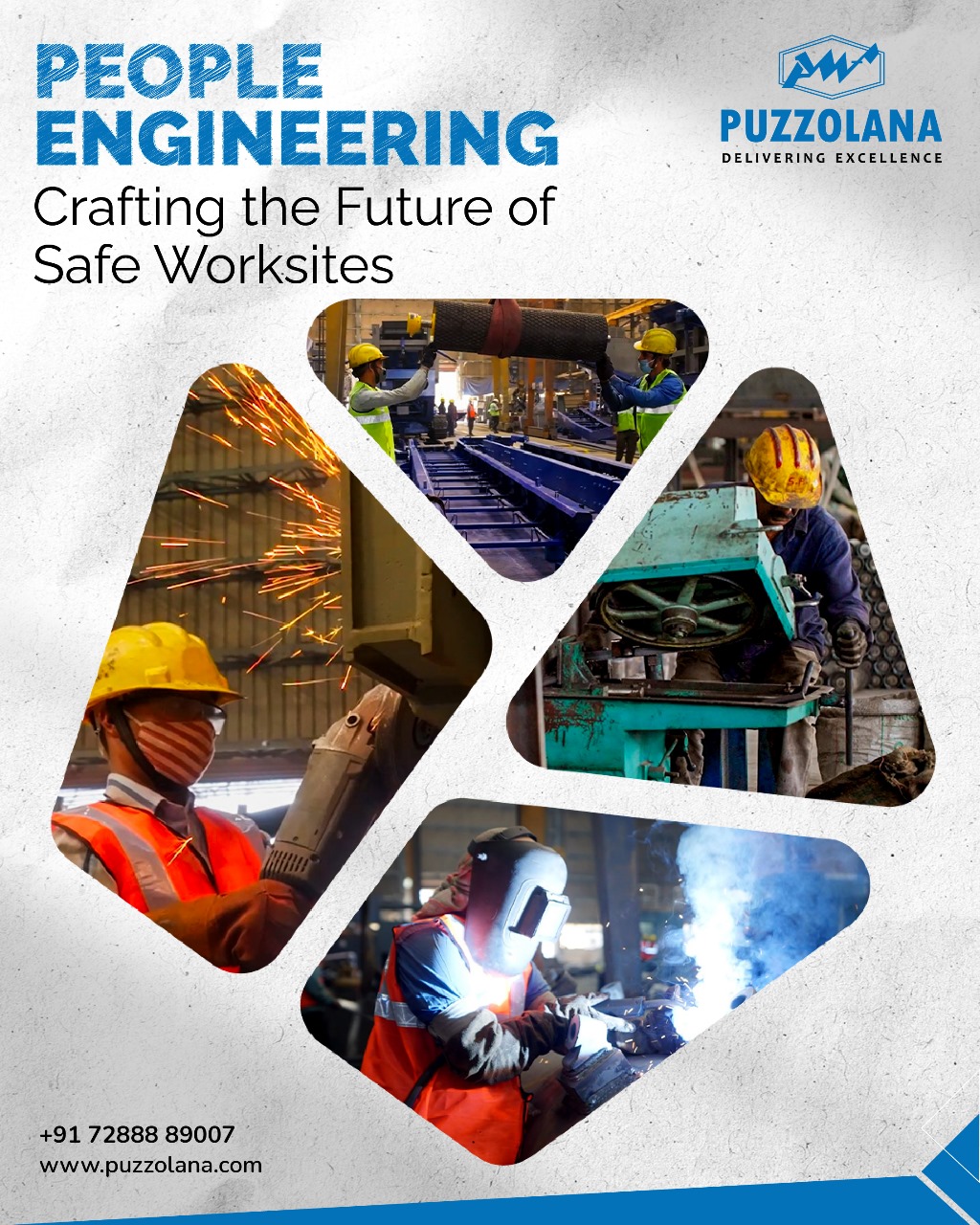

People Engineering: Crafting the Future of Safe Worksites

Blogs

In construction and mining, machines like crushers play a critical role in ensuring work gets done efficiently. However, these powerful machines can pose significant risks if not handled properly. At Puzzolana, we firmly believe that no task is more important than the safety of our people. For us, safety isn’t just a protocol—it’s a daily practice and a core value.

As a global leader in crushing and screening equipment, Puzzolana is committed to designing machines that deliver top performance while safeguarding those who operate them. From our manufacturing floors to job sites across the globe, safety is embedded in every aspect of our operations.

A Safety-First Culture at Puzzolana

At Puzzolana, safety is more than a feature—it’s a mindset. We proactively anticipate risks and implement preventive measures to mitigate them. Rather than reacting to hazards, we empower our teams and clients with proper training and proactive safety practices. We also work closely with plant owners to establish clear safety protocols and provide regular updates. Our ultimate goal is to ensure that no worker is ever put at risk while working on or around our equipment. That’s why our machines are built using robust materials, intelligent engineering, and straightforward operating guidelines—ensuring they are as safe as they are powerful.

Pre-Start Checklist: What to Inspect Before Operating a Crusher

Before starting a crusher, it’s crucial to perform a thorough pre-operation check. Begin by ensuring there are no individuals, animals, or obstructions near the machine—accidents can occur in moments if someone is too close during start-up.

Verify that all safety covers, emergency stop buttons, and guardrails are intact and functional. If any of these components are damaged or missing, the machine should not be operated. Keep the area around the equipment clean and free from hazards such as oil spills, dust accumulation, or loose tools. All bolts and nuts—especially those on load-bearing or moving parts—should be securely fastened.

Finally, inspect the oil and hydraulic systems to confirm they are operating correctly. These systems are vital to the smooth functioning of the machine. Malfunctions can lead to breakdowns—or worse, accidents.

Staying Safe during Operation

Once the crusher is running, constant vigilance is key. Operators must monitor the feed to ensure it enters evenly. Uneven feeding can place uneven stress on the machine, increasing the risk of malfunction or damage.

Be attentive to unusual sounds such as grinding, clunking, or squealing. These could be early warning signs of mechanical issues. If anything seems off, the machine should be stopped and inspected immediately.

Clear communication is also essential. Workers should have reliable methods—whether hand signals, radios, or alarms—to quickly alert each other and coordinate responses in case of an emergency.

At Puzzolana sites, we implement visible signage and designated safety zones. Only trained personnel are allowed in proximity to operating machines, which significantly reduces the chance of injury, even in busy environments.

Engineering Safety into Every Design

Safety is not an afterthought at Puzzolana—it is fundamental to our engineering process. Our machines come equipped with lockout mechanisms to prevent accidental start-ups during maintenance. Emergency stop buttons are strategically positioned for immediate access, and built-in sensors alert operators if temperatures rise or loads exceed safe limits.

We also design for easy maintenance. Accessible components reduce the need to reach into hazardous areas, making routine inspections and cleaning safer and quicker. Every design decision is made with the well-being of the operator in mind.

Partnering with Clients for Safer Workplaces

Our commitment to safety doesn’t end at delivery. We offer extensive training programs, site visits, and support for plant managers to establish and maintain effective safety systems. Regular workshops and refresher sessions ensure teams stay informed and prepared.

We collaborate with industry safety experts and regulatory bodies to ensure our machines meet or exceed global safety standards. At Puzzolana, we see safety not just as a compliance issue—but as our duty.

Whether our machines are operating in India, Africa, or Southeast Asia, we are dedicated to creating job sites that are recognized for their smart, safe practices. That is the Puzzolana promise.

Conclusion: People First, Always

At Puzzolana, safety is not a checklist—it’s a commitment. We believe that machines should empower people, not endanger them. That’s why we design with care, train with purpose, and continually innovate to improve safety.

When workers are protected, machines perform better and businesses thrive. We are proud to lead with both cutting-edge technology and human-centric values, because when people feel safe, they do their best work. And that’s what drives true operational excellence.

View our expansive machinery

With Puzzolana, you have the chance to work with the brightest professionals in the field and be a part of our expanding global footprint. We are looking for motivated professionals to join our team.